Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

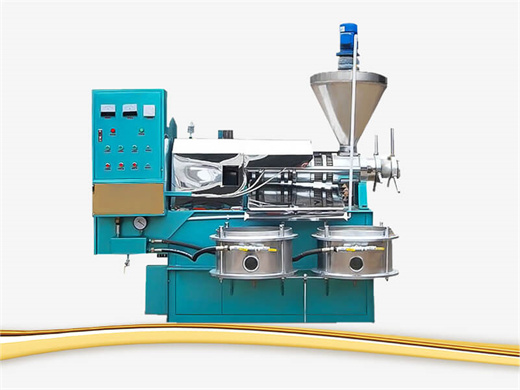

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

vegetable oil press plant cooking oil processing in rwanda

- Use: cooking oil

- Type: cooking oil processing plant

- Production Capacity: 100 kg/h

- Voltage: 220 - 380 volt

- Dimension(L*W*H): 125*35*63 cm

- Weight: 180 KG

- Warranty: 2 years

- Core Components: Motor, Bearing, Gearbox, motor driver

- Oil Thermostat: 600 Watt

- Gear Box: Helical Shaft Gear

- Energy Consumption: 2500 - 3500 Watt/Hour

- Motor Power: 2.2 kW

- Raw material: Stainless Steel

- Function: Making Edible Oil

- Application: Screw Oil Expeller

- Feature: High Oil Yield Efficiency

- Certification: CE - ISO / Food Grade / Conformity to EU

- Market: rwanda

Cost to Setup a Profitable Vegetable Oil Processing Plant

Recent News: Small Cooking Oil Press Machine in Tanzania. Start a Complete Vegetable Oil Processing Plant. Most cooking oil that is used in our homes is extracted from nuts, peanuts, mustard, soybean, coconut and other seeds such as rapeseed, sesame, cottonseeds, etc.

SINODER manufacturing complete vegetable oil press machine, cooking oil refinery equipment, soybean protein factory, animal feed pellet plant, animal oil processing machines, fertilizer machine, industrial drying machines, biomass pellet machines,plastic tyre oil pyrolysis plant and oil distillation plant, egg tray machine and other instruments.

vegetables oil mill plant cost in rwanda - edible oil press

vegetables oil mill plant cost in rwanda,Shortage of soya bean threatens cooking oil manufacturer | The ,Jan 27, 2015 . A multibillion cooking oil factory in Kayonza District, Mount Meru Syco, has been forced to operate under capacity due to shortage of soya bean.

We are in Ghana for business trip from March 15th to March 19th. Anyone one want to buy oil press or want to built vegetable oil plant in Ghana, pls contact me.

turnkey 50-100tpd sunflower oil press in rwanda | Oil Press

50t/d grapesee oil/mustard oil making machinery/production. Dayang oil equipment is a professional manufacturer of oil making machine,supplying oil press We can provide turnkey plant for you: Edible oil refining plant with capacity ranging from 50 t/d to 3,000 t/d.

We offer a wide range of products and services for oil processing, including oil press machines, oil refining equipment, and oil production lines. We also offer free consulting help and professional guidance to help you get the most out of your oil processing investment.

Setting up and running a small-scale cooking oil business

centres on small-enterprise-based drying of fruits and vegetables and processing high value crops such as medicinal plants, spices and essential oils, and small enterprise development. He has co-authored 15 books and numerous articles on the role of appropriate technology in food processing.

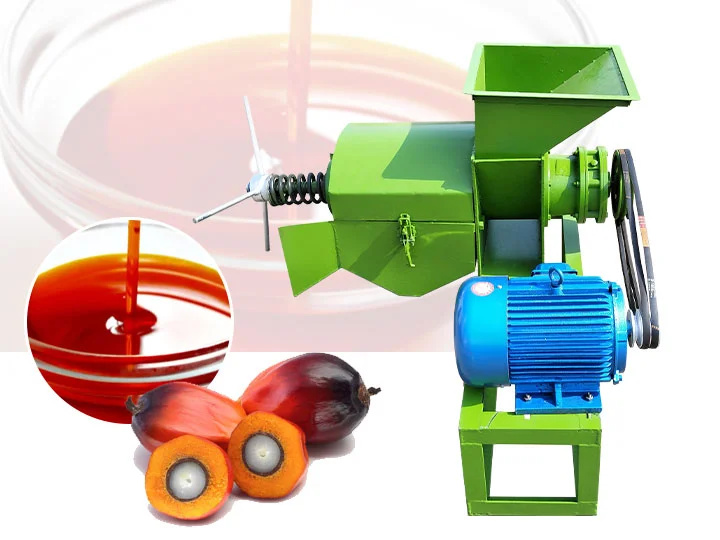

palm kernel oil press extraction machine from rwanda. palm kernel extraction in rwanda edible oil press palm kernel extraction in rwanda. With palm oil production increasing by more than 50% in the last decade of the in relation to. vegetable seeds edible oil machinery pressing plants. Vegetable oil Vegetable oils are oils extracted from plant

Cooking Oil Processing Machines: The Perfect Blend of

Oil screw press machines is preferred for its low power consumption and easy maintenance. This type of equipment is often used in smaller-scale oil mill plants and is suitable for processing seeds like sunflower seeds and soybean. Screw press equipment uses a screw press to extract oil from the seeds, producing a high yield of oil with minimal

Vegetable Oil Mill Machinery Manufacture. Palm Oil Processing Plant , Camellia Seed Extraction Plant , Spiral Oil Press Machine , Cooking Oil Extraction Equipment

Who owns the palm oil processing plant in Ghana?

The oil processing plant was set up in 1995 by an American NGO in collaboration with two Ghanaians. The cooperative had eighty members (60 women and 20 men) and has been in operation since then producing palm oil and palm kernel oil.

How to plan a cooking oil processing business?

One of the first activities when planning an oil processing business is to decide 2 who will be the target customers1. A Market segment is a term that describes an identifiable group of customers. The different types of market segments for cooking oils can be described in five main groups (Table 2.1): Food businesses. Table 2.1.

How many metric tonnes a day does Kumasi refinery produce?

As the company grew bigger, the management bought 4.5 acres of land on the outskirts of Kumasi to set up its refinery in 2007. Now it operates at two premises: the old factory which has a capacity of 50 metric tonnes of crude oil per day and the refinery which has a capacity of 10 metric tonnes per day.

Why is production planning important in oil processing?

Oil processing can be a highly competitive business, and good production planning and management are needed to control product costs, maintain output and increase profitability (see also Chapter 7, Section 7.2). The main considerations in production planning are: Calculating the required production rate to meet the anticipated demand for oil.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!