Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

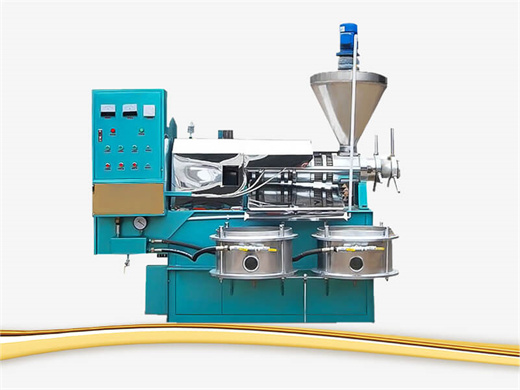

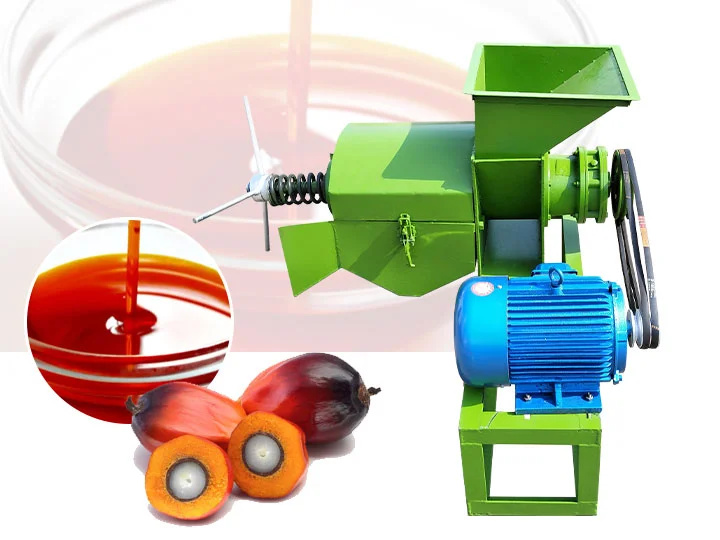

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

engine gzc12qs3 coconut oil processing plant in indonesia

- Use: coconut oil

- Type: coconut oil processing plant

- Production Capacity: 100T~200T/D

- Model Number: Q-0617

- Voltage: 220V/380V

- Power(W): According to the capacity

- Dimension(L*W*H): 1610x615x1260mm

- Weight: 1050 KG

- Certification: ISO9001

- Application: various seeds, lLD cooking etc.

- Grade: high

- Mixed oil concentration: 18-25%

- Supply Solvent residual: < 0.07%

- Market: all the countries

- Index in crude oil: 50-500ppm

- Solvent: hexane

- Oil residue ratio: 1%

- Market: indonesia

Agriculture | Cargill Indonesia

Our oilseeds business is based on palm oil, coconut oil and related derivate products from Indonesia. We also own a copra crushing plant which has given us access to a reliable supply of coconut oil and copra meal. Our capabilities and resources. We operate two main grain storages facilities: in Cigading, Banten; and in Surabaya, East Java.

Every single component that make up a Coconut tree can be processed into a myriad variety of products, leaving no waste to the environmentCoconut is such a versatile crop, which derivatives can all be marketed as high value commodities. At the moment, most coconuts in Halmahera (where #Dewacoco is located) is only produced into black copra. It is crucial to raise awareness and knowledge of the

Coconut Oil Processing Plant - Manufacturer Exporter Supplier

The Copra Oil Production Plant is in great demand across various countries where the production of Coconut is significant. Basic equipment / machinery required for the Copra Oil Production Plant is as under :

PT PULAU SAMBU (KUALA ENOK) was established in 1967 as SAMBU GROUP’s first coconut oil processing plant. The plant produced crude coconut oil, refined bleached and deodorized coconut oil as well as copra expeller for the export market. All products were eventually developed and certified in accordance to international standards.

Integrated Coconut Processing Plant - Nucla Mitra Indoindah

Indonesia is a coconut paradise. This leads us to develop coconut products and distribute them within various countries in order to meet global demand. Starting from our success in developing various coconut product supported by an experienced workforce.

Indo Vegetable Oil Industri, which has been established for over 30 years in edible oil industry. We are producing Crude Coconut Oil (CNO), Cooking Oil (RBD CNO), RBD Hydrogenated CNO (RBD HCNO), Coconut Fatty Acid Distillate (CFAD), and Copra Meal. PT. Golden Union Oil is a privately owned company with a broadly diversified customer base.

How is Coconut Processed From a Plant into Oil and

How does Musim Mas source copra and process it into coconut oil and derivatives, such as coconut-based surfactants that go into shampoos we find on supermarket shelves? Sourcing from Coconut Smallholder Farmers All of Musim Mas’ copra supply originates from small farms in Indonesia. Most of these smallholders work independently.

Tingkat 25, Blok A Menara Kinabalu Jalan Sulaman, Teluk Likas, 88400 Kota Kinabalu, Sabah, Malaysia +6088-369171/369150 info@bimp-eaga.asia Connect with Us

Roxas Sigma's World Class Coconut Processing Plant

Our Plant has a total area of 21,945 square meters which houses our Main Production, Utilities, and Administration buildings. The Main Production building covers the areas for fruit receiving, sorting, washing, de-shelling, paring, extraction, processing, and packing operations.

Customers sometimes express the desire to produce multiple types of cooking oil using a single machine. In response, it should be noted that high oil-content raw materials typically undergo pretreatment, pre-pressing, and solvent extraction methods, whereas low oil-content raw materials are directly used in the refining method after the pretreatment.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!