Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

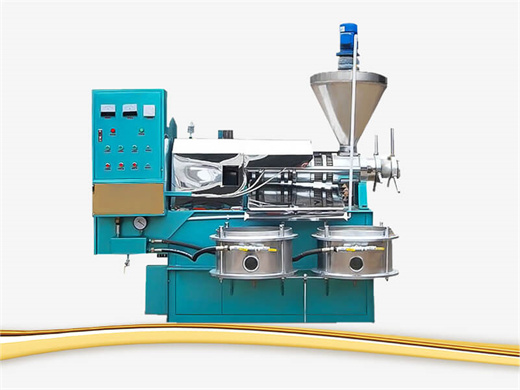

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

manufacturer small scale oil refinery plant in ghana

- Use: edible oil

- Type: edible oil refinery plant

- Voltage:380V

- Power:2.2KW

- Dimension(L*W*H):1910*550*765 mm

- Weight:Based on Oil Purifying Machine capacity

- Certification:ISO9001

- Raw Material:Vegetable Oil Suitable for Soybean,Peanut,Kernel,Coconut

- Material:Stainless and Carbonless Steel

- Cooking Oil Machinery Process:Pre-treatment,Solvent Extraction,Refining

- Pretreatment Process:Cleaning,Hulling,Breaking,Soften,Flaking,Puffing,Toasting

- Solvent Extraction Process:DTDC,Miscella Toasting and Stripping,Solvent Collecting,etc

- Service:Engineer Abroad Erection

- Refining Process:Degumming,Deacidification,Deordorization,Decoloration,etc

- Process Capacity:500TPD Oil Purifying Machine

- Packing:Frame and Container

- Market: ghana

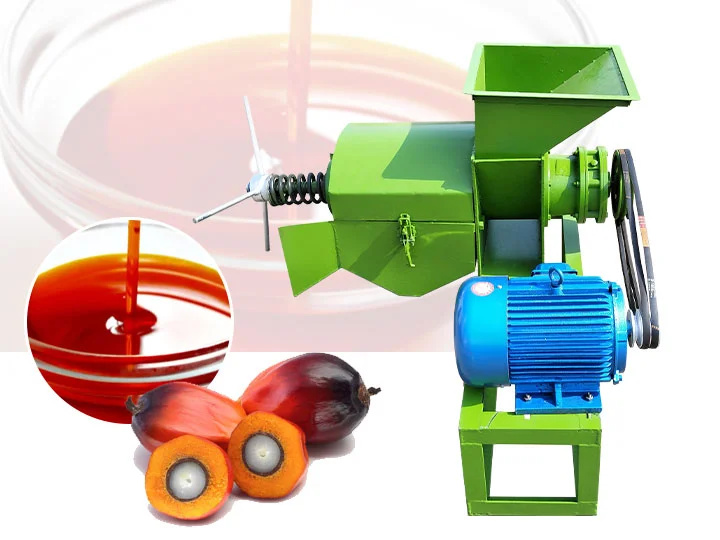

Small scale palm oil refinery plant

Our small scale palm oil refinery plant are great choice for small capacity oil refinery machine. The small scale palm oil refining production plant can remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the oil. Small Scale Palm Oil Refining Plant Process Flow: Crude Palm Oil—–Degumming—–Neutralizing

It also stabilises, neutralizes, degums and bleaches the oil. Sometimes even further steps are desirable at manufacturing plants, including winterization (a type of fractionation), dewaxing, or changing how the oil melts. (Learn more about crude oil refinery plant cost >>) Vegetable Oil Refinery Machine, 1ton/day (left), 2ton/day (right)

Mini Scale Soybean Oil Processing Plant for Small Business Plan

This mini soybean oil processing plant is our latest soybean oil plant appropriate especially for processing under 10 tonnes every day. Toggle navigation info@abcmach.com

For over 30 years TINYTECH® has been designing, manufacturing and installing plants for customers in more than 50 countries across the world. We create precision solutions to meet widely varying customer-specific and regional situations and requirements.

Guidance for Establishing a Small Scale Mustard Oil Mill Plant

Landing Producing Contries of Mustard Seed in 2017 / 2018 (in million metric tons) We have designed and set up many oil mill plants all over the world, even though our mustard oil making plant is mainly based in Bangladesh and India.

Waste Oil to Diesel Plant. PPGT-DF Waste Oil Distillation Plant is designed to crack the long chain hydrocarbons of waste motor oil into valuable diesel fuel, and some byproducts, such as light hydrocarbons, water and asphaltene sludge.

Modular Refineries | Amerisource Energy

A modular refinery is a prefabricated processing plant designed to distill crude oil into naphtha, kerosene, diesel, residual fuel oil, and off-gas using a crude distillation unit (CDU). These initial petroleum products could be further treated using secondary process equipment (hydrotreating and reforming units) to produce high-octane gasoline

Offer Customized Cooking Oil Refining Plant. After oil is extracted from vegetable seeds, the crude oil should go through a number of different processes in cooking oil refinery plant to make it ready for human consumption.

Small Scale Palm Oil Refinery Machine Selection and Process

In order to meet the needs of small-scale palm oil extraction workshop, ABC Machinery has successfully developed this complete small scale palm oil refinery plant to achieve the integration of flow of dephosphorization, degumming, deacidification, dehydration and decolorization.

In order to meet the needs of small-scale palm oil extraction workshop, Huatai Machinery has successfully developed this complete small scale palm oil refinery plant to achieve the integration of flow of dephosphorization, degumming, deacidification deodorization. The following photos are about one of our 1TPD palm oil refining project suitable

Who owns the Ghanaian oil refinery?

The refinery was first named the Ghanaian Italian Petroleum Company (GHAIP). It was licensed as a private limited liability company in 1960 as a fully owned Italian company ¨C ANIC Societa per Azioni and AGIP Societa per Azioni of Italy were its major shareholders. In April 1977, the Government of Ghana became the sole shareholder.

What is a modular refinery?

Modular mini-refineries (which can be as small as 1,000 bpd nameplate capacity) typically have the advantage of being located close to their source of crude oil, thus minimising logistics and distribution costs. Plant modules can also be joined together to create a much larger refinery of 100,000 bpd or more, should demand dictate.

Who owns Tema Oil Refinery?

The Tema Oil Refinery (TOR) is one of two crude oil refineries in Ghana. In 1977, the Government of Ghana became the sole shareholder. The name of the refinery was changed to the Tema Oil Refinery in 1991. The refinery was first named the Ghanaian Italian Petroleum Company (GHAIP).

What is the storage capacity of Fujairah refinery?

When completed, the Fujairah refinery will have a total storage capacity of 91,000 cm for handling naphtha, diesel, gas oil, fuel oil, kerosene, slop (the collective term for mixtures of oil, chemicals and water derived from a wide variety of sources) and water.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!