Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

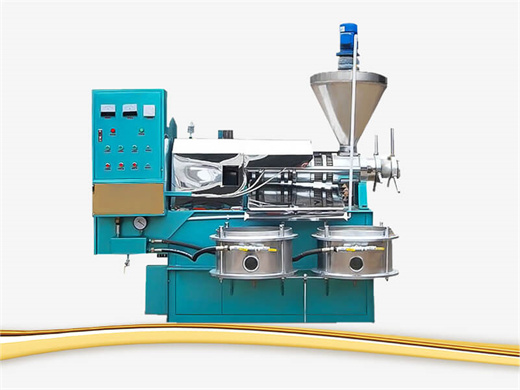

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

automatic argan mustard oil refinery plant in malawi

- Use: argan oil

- Type: argan oil refinery plant

- Production Capacity:10-100TPH

- Model Number:DT100

- Voltage:220V/380V/440V

- Power(W):10-50kw

- Dimension(L*W*H):1200*400*900mm3

- Weight:According to oil refining capacity

- Certification:ISO9001/CE/BV

- Warranty:12 Months, long term technical support

- Plam kernerl oil refining machine:Available

- Keywords:oil refinery and fractionation machinery facility

- Raw material:fruit, kernel

- Feature:High efficient and environment protection

- Factory Area:According to the capacity and the actual situation

- Residual:Less than 2%

- Technology:Introduce Malaysia high technology

- Material:Parts of are stainless steel

- Product name:oil refinery and fractionation machinery facility

- Market: malawi

Small Mustard Oil Mill Plant of Pressing & Refining Built in

This 5TPD mustard seed oil pressing and 1TPD oil refinery plant invested by a local company was built in Manipur, a north-east state in India. This small mustard oil mill plant was the first mustard oil processing plant in the seven states of Indian North-East region, where has the richest soil in India to produce high quality mustard seeds.

Bleaching. This is one the important stage in total refining process. Where the oil is heated to 100 deg c to 105 deg c and mixed with Bleaching earth chemical ( Acid activated clay) and also activated carbon in a vessel under vacuum at 70 mm hg where the stirring continues for specific designated time and then filtered the oil to remove the clay and carbon.

Automatic Commercial Sunflower Mustard Cooking Oil Mill in Malawi

Taking in consideration of the further oil production requirements, the pretreating section was also equipped with delinter, crusher, screening sieve, cooker, single screw oil presses and one set small oil refinery unit so that the whole oil processing factory can process more plant seeds, not only sunflower seeds, soybean and cottonseeds.

Bakhresa Malawi Limited, a subsidiary of Tanzania-based conglomerate Bakhresa Group, is setting up a $100 million cooking oil manufacturing plant in Blantyre. The investment would be a boost to Malawi’s efforts to spur economic activity with a guarantee of employment, a ready market for oil seeds such as soya and competition on the cooking

Mustard Oil Expeller - Automatic Mustard Oil Mill Plant

Mustard Oil Expeller is used for Mustard Oil Extraction and crushing the mustard oilseeds on the machine. Our TINYTECH Mustard Oil Expeller is unique and comes with many features:-1) Chamber Cage opens on hinges only.

Oils Fats Refining Equipment and Turnkey Plants. We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Physical Refining Edible Oil, Vegetable, Cooking Oil Refinery

Spectec Techno Projects Pvt. Ltd manufactures, supply & Exports Physical Refineries for Vegetable Oil, Cooking oil , edible oil for refining high FFA Oils like Rice Bran Oil, Hazel Nut Oil, Palm Oil & Palm Kernel Oil.

address Tinytech Plants Tagore Road, Near Atul Motors, Near Bhaktinagar Railway Station Circle, Rajkot - 360002, Gujarat, India Get Directions

Oil Refinery Plant - Soybean Oil Refinery Plant Exporter from

Exporter of Oil Refinery Plant - Soybean Oil Refinery Plant offered by Mitsun Engineering, Vadodara, Gujarat.

Equipment & Machinery are Required to Start a Mustard Oil Processing Plant. Mustard oil extraction involves a different process. The detailed mustard oil processing process includes seeds selection and cleaning, conditioning, oil pressing, and oil filtering. The required equipment for every process is listed below. Seed Cleaner

How to improve the quality of edible mustard oil for human use?

For improving the quality of edible mustard oil for human use. Double filter press is highly recommended for any mustard oil plant as it removes the foots and also gives a shining effect to the oil. Optionally a Polish filter can be added before final storage to further polish the filtered oil.

How to extract mustard oil?

The extracted mustard oil by pressing contains suspended particles (foots). For improving the quality of edible mustard oil for human use. Double filter press is highly recommended for any mustard oil plant as it removes the foots and also gives a shining effect to the oil.

How a mustard oil Machine Works?

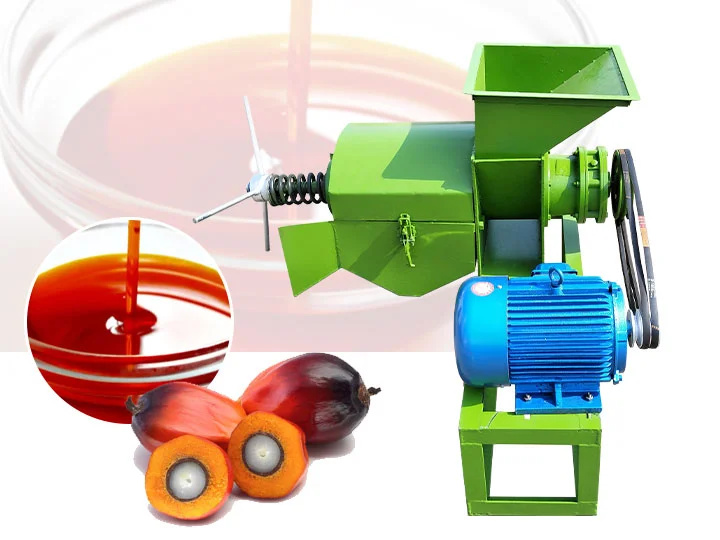

The machine crushes and squeezes oil from the mustard seeds without adding any chemicals & Heat. Therefore, the oil produced by the machine is Cold Press, Healthy and Free from any sort of toxins. The extracted mustard oil by pressing contains suspended particles (foots). For improving the quality of edible mustard oil for human use.

How mustard seed oil extraction machine works?

The working principle of mustard seed oil extraction machines is to vigorously push mustard seeds through the chamber by the action of rotating screws. Under the high pressure of the chamber, there is great friction drag between raw material and the worms. It pushes raw material and rolls over outward at the same time.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!