Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

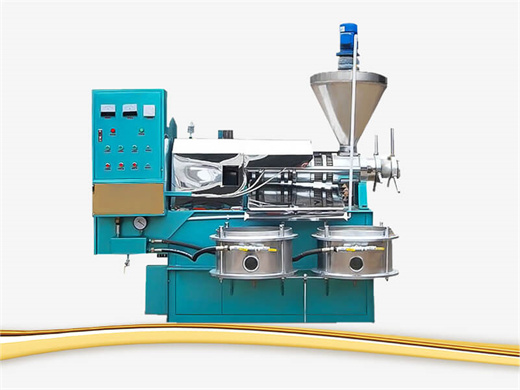

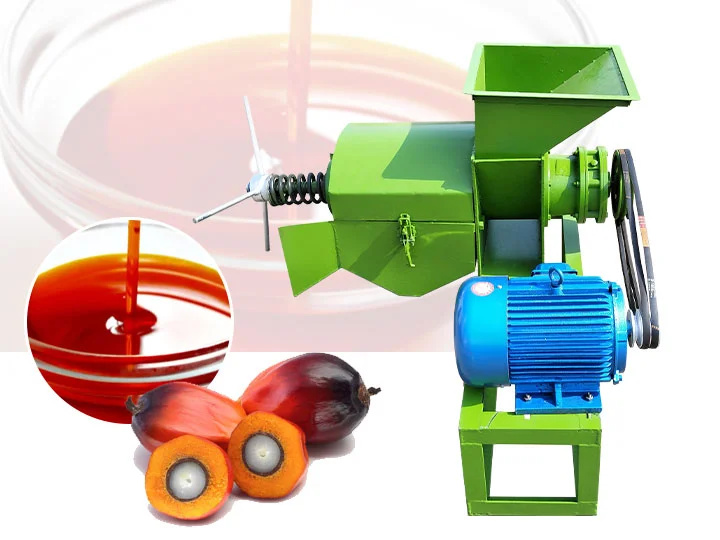

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

crude edible oil refining process plant in cape town

- Use: edible oil

- Type: edible oil refining plant

- Production Capacity:oil refinery

- Model Number:oil extraction machine, oil refinery

- Voltage:depend on oil extraction machine, depend on the capacity

- Power(W):depend on oil extraction equipment, depend on the capacity

- Dimension(L*W*H):depend on oil extraction equipment, depend on the capacity

- Weight:depend on oil extraction equipment

- Certification:ISO9001

- After-sales Service Provided:Engineers available to service machinery overseas, Engineers avto service machinery overseasailable

- Steam consumption:based on oil extraction machine

- Color:based on oil extraction machine

- Residual oil in meal:Less than 1%

- Crude oil moisture and volatile matter:Less than 0.30%

- Market: cape town

edible sunflower oil refinery plant in cape town

edible sunflower oil refinery plant in cape town . Production Capacity: 100; Voltage: 220V/380V; Weight: 1000 KG; Key Selling Points: High Productivity

The refining process is like giving it a spa treatment. Crude palm oil, as the name suggests, isn't perfect yet. It contains some things we don't want, like impurities and odors. That's where refining comes in. Hence, in the second stage of palm oil process, we discuss refinery process of crude palm oil. Refinery of Crude Palm Oil

Edible oil Refining - Degumming / Neutralization - Edible Oil

One of the key steps in the refining process is the elimination of impurities from crude vegetable oils, especially the phosphatides or so-called gums. They need to be removed for two main reasons: they are responsible for high refining losses and they decompose, darken the oil due to their thermal instability. We Follow Different Routes For Different Oils: Low FFA […]

At our 15 refineries our throughput capacity of crude oil and other feedstocks is 3.2 million barrels per day. Depending on the size of the refinery, from 80,000 to 300,000+ barrels of crude oil per day, per refinery, is processed to make clean transportation fuels.

Processing - Wilmar International

Our edible oils are derived from refining crude palm oil, which are obtained from both our own plantations and third-party suppliers, as well as a wide range of oilseeds including soybean, rapeseed, groundnut, sunflower seed, sesame seed and cotton seed.

The crude oil is obtained by crushing the beans or seeds, the subsequent refining can be done either chemically or physically. GEA has extensive process line expertise for all the stages that contain centrifugal separators and decanters as well as for the production of high-quality by-products, i.e. lecithin and glycerine.

About Astron Energy - An Organisation Driven By Energy

We own and operate the country’s third-largest crude oil refinery in Cape Town, which has a daily nameplate crude processing capacity of 100,000 barrels and a lubricant manufacturing plant in Durban. Part of South Africa’s history for over 100 years

The major sources of dietary lipids are edible oils, which include both vegetable and fish oils. Crude oil extracted from vegetable and fish sources contain mono-, di-, triacylglycerols along with

edible cooking semi soybean oil refinery plant in cape town

What is a small scale edible oil refining plant? 1-10TPD small scale edible oil refining plant manufactured by Henan Doing company has won the national patent.Our small scale edible oil refining plant are great choice for small capacity oil mill.The small scale oil refining plant can remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other […]

Figure-1: Physical and chemical refining of edible oil16. Hot oil Figure-2: Degumming step of edible oil refinement. Physical Refining Acid- Degumming Dewaxing Bleaching Deacidification/ Deodorization acids Gums Fatty Edible Oil Crude Edible Oils Chemical Refining Water-Degumming Gums Drying Alkali- Neutralization Bleaching Deodorisation

How is crude oil processed in Cape Town?

Crude oil arrives by oil tanker in Saldanha Bay for discharge and is then transported to Cape Town refinery via pipeline. Our team is then responsible for converting the crude oil into final products including LPG, petrol, jet fuel, diesel and fuel oil. Starts in the distillation towers, where crude oil is separated into various components.

How does crude oil refinery work?

Starts in the distillation towers, where crude oil is separated into various components. These components are then further processed and treated to produce final products. Some of the processes used at the refinery are hydrotreating, cracking and reforming.

Where is our refinery located?

Our refinery is located between residential communities in the Cape Town area, so we take extra care to make sure we take the necessary steps to protect our employees, their families and our neighbouring communities. Petroleum refining is one of the most heavily regulated industries in the world.

What processes are used at the refinery?

Some of the processes used at the refinery are hydrotreating, cracking and reforming. The refinery also uses processes to remove impurities in the component streams, the most significant of these impurities being sulphur. when processed.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!