Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

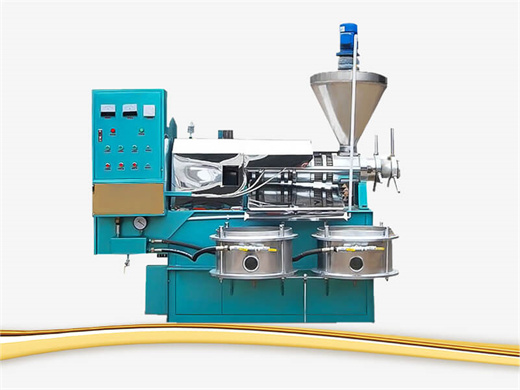

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

manufacturer palm oil refinery plant equipment in lesotho

- Use: palm oil

- Type: palm oil refinery plant

- Production Capacity:5TPD-100TPD

- Voltage:380V/50HZ

- Dimension(L*W*H):1510*440*700mm

- Weight:330kg

- Core Components:Motor

- item:essential oil extraction equipment

- price:bottom price ,factory price ,best price

- Section:Pretreatment,extraction, refining

- scale:large scale,small scale,mini scale

- Oil rate:meal residual:≤ 1%,press cake residual:≤ 6%

- color:different according to request

- raw material:sesame, sunflower, cottonseeds,rapeseeds,peanuts

- Material:carbon steel & stainless steel

- Raw material:Oil Seeds

- After Warranty Service:Video technical support, Online support

- Certification:CE, ISO

- Market: lesotho

Oils Fats Refining Equipment and Turnkey Plants

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Crude Palm Oil (CPO) is mainly further processed into edible oil for food purpose. To meet the international industry’s standards for edible oil, the crude palm oil produced by oil mills should be refined in palm oil refinery plan t. Palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and

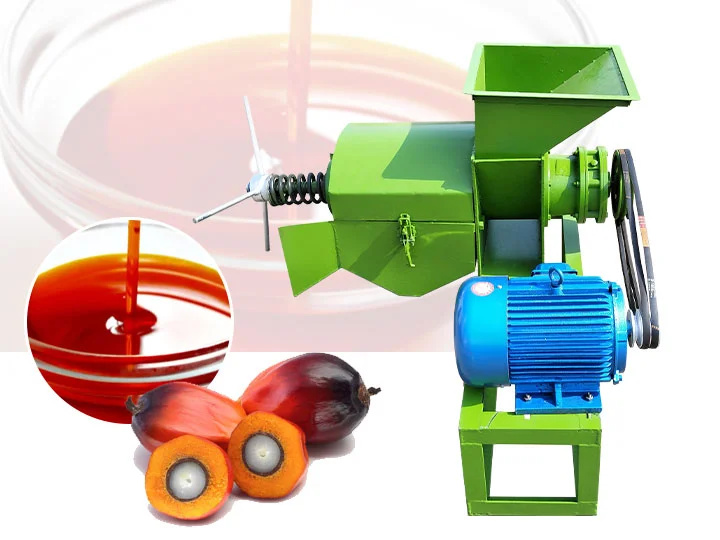

Palm oil milling equipment and machinery

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as

After processed in palm oil refinery plant, the crude palm oil can be processed into edible oil of consistent quality, which satisfies customers’ requirements and industry standards in respect of Iodine value, FFA, flavor, color, melting point, peroxide value, impurities and moisture. Successful Projects of Palm Oil Refinery Plant

Everything You Need to Know About Palm Oil Refinery Process

Malaysia is the largest exporter and producer of crude palm oil in the world. The crude palm oil is gathered from the mesocarp of the palm oil. However, the crude palm oil that has been extracted contains unwanted impurities and requires a refining process to partially or eliminate them to produce edible oil.

Oil Mill Plant For Total Solution. Oil Mill Plant Manufacturer with 67 years experience. Offers tailor-made turnkey solutions from designing, installation to commissioning and maintenance of oil mill machinery.

palm oil processing equipment/palm oil refinery plant/palm

ABOUT QI'E GROUP. QI'E Group is a large-sizd joint-equity enterprise specializing in the production of edible oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for palm oil and palm kernel oil production.

A modular refinery is a prefabricated processing plant designed to distill crude oil into naphtha, kerosene, diesel, residual fuel oil, and off-gas using a crude distillation unit (CDU). These initial petroleum products could be further treated using secondary process equipment (hydrotreating and reforming units) to produce high-octane gasoline

Palm oil refining equipment

Dingsheng Machine is a leading manufacturer for animal fat extraction and refining solutions and equipment in China. We provide professional technology and solutions, whether you specialize in fats from land-based animals such as cows, pigs or chickens, or work in the production of fish oils.

Brissun Technologies Pvt Ltd is a globally established engineering & manufacturing organization with expertise in Oil Refineries Plant, Edible oil mill refinery & extraction plants manufacturers, supplier & Exporter From India

Why did Malaysian palm oil refiner Ban Dung invest in a centrifuge?

By investing in an Alfa Laval PANX 800 decanter centrifuge, Malaysian palm oil refiner Ban Dung has increased capacity while also reducing the level of product waste in their production. With improved energy efficiency, they have even achieved lower overall operational costs. Hear their story in this video.

What is Alfa Laval LKH?

The Alfa Laval LKH premium centrifugal pump is known for high pump efficiency, gentle product treatment, chemical resistance, and operation at high pressure and a broad range of flow rates. For supplying steam needed in deodorization processes and the physical refining of oils and fats.

What are the different types of edible oil refining processes?

A full range of edible oil refining processes from crude to refined oils. Find out how we can help you. A full range of fat modification processes such as fat hardening, interesterification (chemical or enzymatic), dry fractionation and semi-continuous deodorization. Find out more.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!