Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

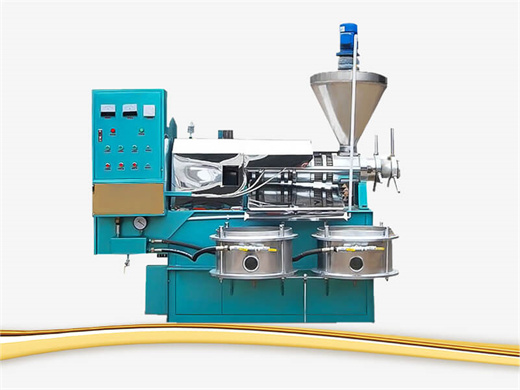

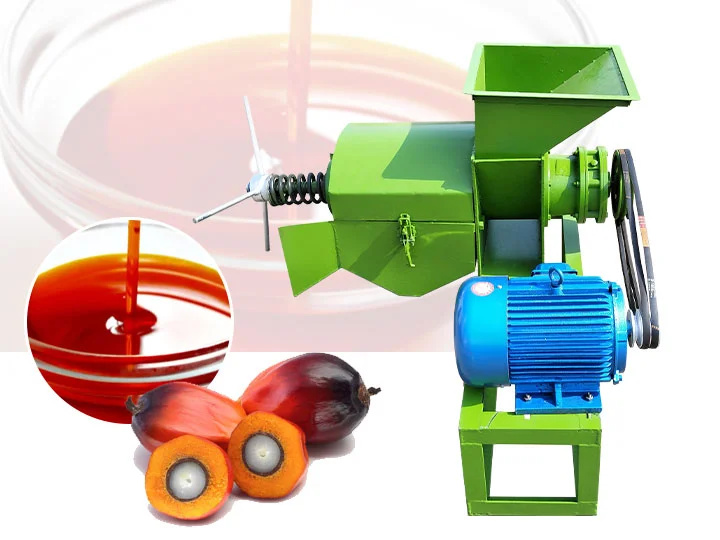

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

soybean oil extraction and refining equipment in iraq

- Use: soybean oil

- Type: soybean oil refining equipment

- Production Capacity:10 -5000TPD

- Model Number:JXPI 498

- Voltage:380v 440v

- Power(W):As seed oil press oil refinery output every day

- Dimension(L*W*H):As per oil press oil refinery output

- Weight:As oil press oil refinery capacity

- Certification:ISO9000

- Item:oil press oil refinery

- Material:stainless steel

- Process of oil making:pretreatment ,leach ,refinery ,packing

- Rate of extraction:12-18 %

- Residual oil in meal after extractoin:less than 1%

- Solvent consumption:less than 2kg/t

- Power consumption:not more than 15KWh/T

- Oil grade of oil:one ,two ,three ,four grade

- Protein rate of oil:general is 55% ,transgenosis 650-7000%

- Market: iraq

Refining Vegetable Oils: Chemical and Physical Refining - PMC

1.1. Chemical Refining of Oil. Chemical refining is the traditional method used since ancient times. It can be used for all fats and oils even when they have been slightly degraded. Each step of the refining process has specific functions for removing some undesirable compounds. Chemical refining follows six processes:

Soybean Oil Extraction Technology illustration. Usually, when the processing capacity of oilseeds is more than 20 tons/day, the extraction methods can be selected to produce soybean oil, which can reduce the production cost of soybean oil and obtain more profits. The Difference Between Soybean Oil Extraction Methods and Pressing Methods

Soybean Biorefinery: Process Simulation and Analysis

The product of soybean oil extraction with ethanol is a miscella (oil + solvent) that, after cooled down to less than 30 °C, separates into three phases: rich-in-alcohol miscella (poor miscella

Sama Al Manar will own the largest soybean crushing plant in Iraq in near future. Sama Al Manar is the one of the partnership company of Tiryaki A.Ş. Since 1965, Tiryaki has evolved into the sector leader in Turkey processing agricultural products such as pulses, grains, nuts, organics, feed and oilseeds with an exemplary supply chain.

Soybean Oil Refinery Plant Manufacturer & Exporter - Goyum India

Degumming. This is first step of soya bean oil refining where all the phosphatides will be removed. This will be taken into two steps. Step 1 mixing with hot water at 65 to 70°C allowing to react and gums will be separated with centrifuses, heavy phase will be gums and light phase will be de gummed oil.

The soybean oil can be further refined from a crude product to an edible product. Oil Refining and Processing. Extracted and desolventized soy oil must be further processed to make an edible product. Edible oils are refined to improve the flavor, odor, color and stability using processes that degum, neutralize, bleach and deodorize the oil

Soybean Oil Processing Byproducts and Their Utilization

Refining of soybean oil to make a neutral, bland-flavored, and light-colored oil results in several byproducts. Fig. 17.1 diagrams the conventional refining process and shows the byproducts that are generated at each stage. Download : Download full-size image; Fig. 17.1. Processing diagram for soybean oil.

The complete soybean oil manufacturing process requires a series of oil processing machine based on the specific processing steps, including cleaning machine, cooking machine, oil extraction machine, oil filter machine, solvent extraction plant, oil refining plant, and more. The selection of soybean oil processing machine should be closely

Start Soybean Oil Production Factory at Low Cost in Nigeria

Oil is used for three meals a day. Soybean oil is an edible product with rigid market demand. For investors who are starting a business for the first time or young people returning to start a business in their hometown, the development of a small soybean oil processing plant is an asset-light, low-risk, and promising project.

Furthermore, when extruded soybean oil was treated with cellulase alone and with a mixture of cellulase and protease, no significant augmentation of soybean oil yields (68%) was observed. However, when the same oleaginous material was treated with protease it resulted in 88% of soybean oil . It clearly elucidates that the hydrolysis of protein

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!