Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

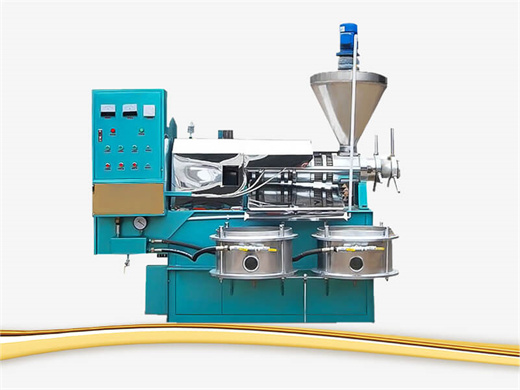

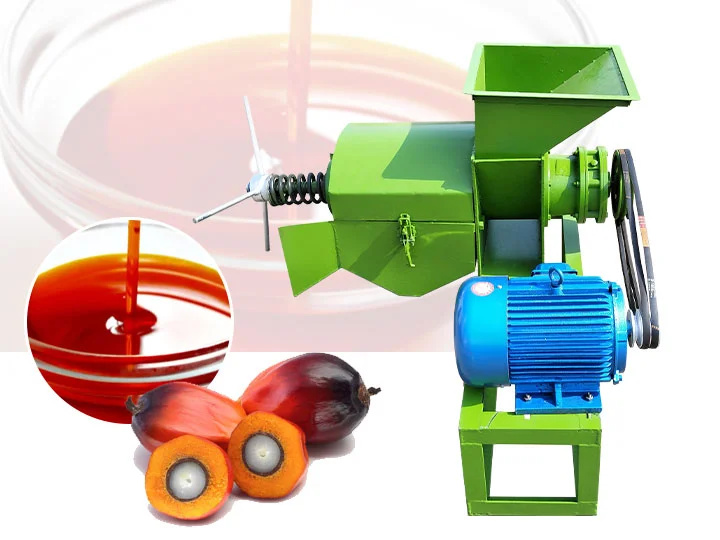

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

crude oil refinery plant for refining soybean in germany

- Use: soybean oil

- Type: soybean oil refinery plant

- Production Capacity:depends on the capacity

- Voltage:380 voltage

- Dimension(L*W*H):depends on the capacity

- Weight:600 KG

- Warranty of core components:5 years

- Core Components:Motor, Engine

- Oil color:white

- capacity:1-100t

- power:32kw

- size:according to the capacity

- name:edible oil industry equipment

- function:refine kinds of vehetable oil

- oil quality:clear, transparent, odorless

- production time:30 days

- service:arrange technicians to factory of user for instruction

- Market: germany

Soyabean Oil Refinery Plant

Soyabean Oil Refinery by Tinytech comes in various capacities ranging from entry level small scale plant of 5-TPD to medium and big scale plants upto 30-TPD. We are leading manufacturers and exporters of Soyabean Oil Refinery Plant systems for processing the crude soya oil into the refined soya oil.

Second Stage of Vegetable Oil Refining Process Neutralization or simply Neutralizing is the second process in the vegetable oil refining which commences after degumming completion. The feedstock is taken into the Neutralizers where the heating temperature range is kept at 55 C to 70 C depending on the quality of crude oil.

Soybean Oil Extraction Plant | Soybean Oil Plant Manufacturer

Crude soybean oil contains a relatively high concentration of phospholipids compared with other vegetable oils. Degumming is a process of removing these components from crude soybean oil to improve its physical stability and facilitate further refining at the soyabean oil plant.

Renovation driven by strong global demand in food and energy markets . ST. PAUL, MINN. (September 07, 2021) - CHS Inc., the nation’s leading agribusiness cooperative, today announced a major soybean refinery expansion and renovation project at the CHS Mankato, Minn., soybean processing plant, driven by global oil demand.

Refining Vegetable Oils: Chemical and Physical Refining - PMC

1.1. Chemical Refining of Oil. Chemical refining is the traditional method used since ancient times. It can be used for all fats and oils even when they have been slightly degraded. Each step of the refining process has specific functions for removing some undesirable compounds. Chemical refining follows six processes:

Along with improvements to fully optimize soybean oil refining, related Mankato plant improvements include upgrading and expanding the entire refining process, and improving process flows to

Degumming Process in Oil Refining Plant

What is Degumming Process in Oil Refining Plant? Degumming process in oil refining plant is to remove gum impurities in crude oil by physical or chemical methods, and it is an oil purification process. After screw pressing and solvent extracting from oilseeds, crude oil mainly contains triglycerides and few non-triglyceride.

One of the key steps in the refining process is the elimination of impurities from crude vegetable oils, especially the phosphatides or so-called gums. They need to be removed for two main reasons: they are responsible for high refining losses and they decompose, darken the oil due to their thermal instability. We Follow Different Routes For Different Oils: Low FFA […]

Edible Oil Refining: Current and Future Technologies

In edible oil refining, the continuous effort to reduce overall production costs is mainly achieved by increasing plant capacities, installation of mono feedstock plants, and increasing the degree of automation. Over the years, more energy-efficient processes and technologies, resulting in a higher refined oil yield, have gradually been introduced.

SOMERSET, Ky. (Dec. 21, 2021) — Continental Refining Co. breaks ground on the company’s new soybean crushing, biodiesel refining and blending facility in Somerset, a project creating 20 full

Why is BP refining oil in Germany?

BP Plc plans to scale back its oil-refining operations in Germany due to high costs and declining demand for fuels. Its Gelsenkirchen oil-processing complex will become the second German plant to reduce crude consumption from 2025, with Shell Plc working on a similar move at a nearby plant.

Where is the largest oil refinery in Germany?

MiRO GmbH & Co. Refinery KG is located in Karlsruhe, Baden-W¨¹rttemberg. The plant is the largest oil refinery in Germany and one of the most modern and powerful plants in Europe. Capacity - 14.9 million tons per year (Rosneft's share in capacity is 3.6 million tons per year), the Nelson complexity index is 9.4.

How important is crude oil in Germany?

Crude oil will remain one of the most important sources of energy in Germany for decades to come. PCK processes 12 million tons of this valuable raw material every year, placing it among the largest crude oil processing facilities in Germany.

Why is BP reducing crude processing capacity in Germany?

REUTERS/Chris Helgren/File Photo Purchase Licensing Rights HOUSTON, March 20 (Reuters) - BP (BP.L) plans to reduce the crude processing capacity of its Gelsenkirchen oil refinery in Germany by around one third from 2025 due to a weaker demand outlook, its head of refining Amber Russell said on Wednesday.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!