Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

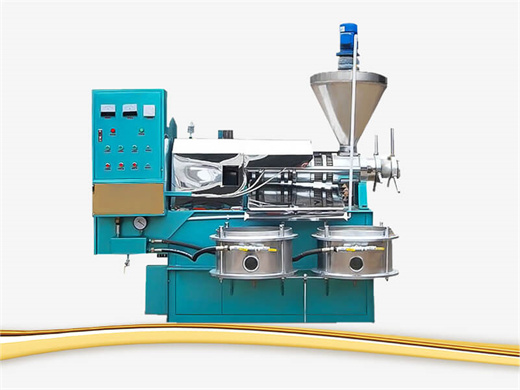

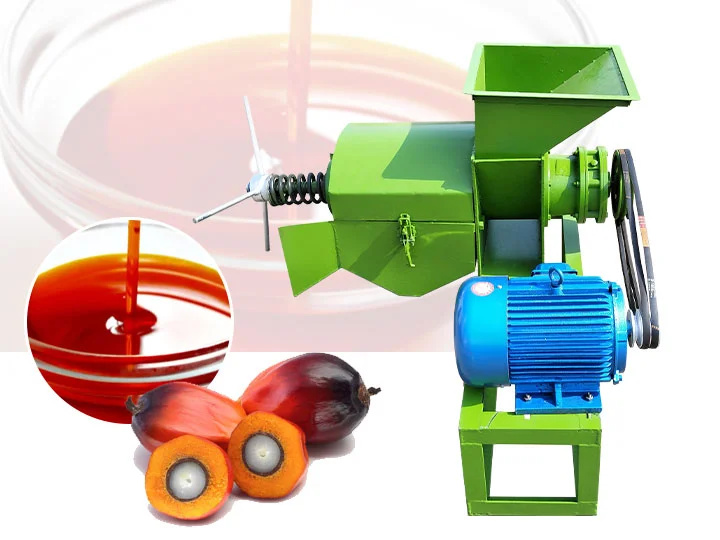

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

vegetable seeds oil cake solvent extraction plant in johannesburg

- Use: vegetable oil

- Type: vegetable oil extraction plant

- Production Capacity: according to the capacity

- Model Number: QIE cooking oil machine

- Voltage: 220v,380v,440v

- Power(W): according to the capacity

- Dimension(L*W*H): 430*230*350

- Weight: 1050 KG

- Certification: CE,BV,ISO

- name: small hand press

- raw materials: fresh Sunflower

- texture: stainless steel,carbon steel

- package: wooden case special for cooking oil machine

- other materials: cooking ,cooking ,Cooking , Sunflower

- using popular area: Srillanka, Malaysia,Phillipine,Nigeria,America tropical area

- main business: South East Asia,Middle America,West Africa

- using life: more than 15 years

- Material: Stainless Steel 304

- Market: johannesburg

Towards an energy-friendly and cleaner solvent-extraction of

For a large scale process as applied in other oil seed extraction, e.g. 100 ton/h soya bean oil extraction, the desolventizer/toaster for soya meal operates at a slightly higher temperature and more energy will be consumed because of a higher proportion of oil cake. Energy savings and emission reductions are shown in Supplementary Information

Over recent years, the food industry has striven to reduce waste, mostly because of rising awareness of the detrimental environmental impacts of food waste. While the edible oils market (mostly represented by soybean oil) is forecasted to reach 632 million tons by 2022, there is increasing interest to produce non-soybean, plant-based oils including, but not limited to, coconut, flaxseed and

Recent advances in green soybean oil extraction: A review

The pressurized liquid extraction (PLE) was assessed by Mello et al. [102] using methyl acetate as a solvent to extract crambe seed oil. A higher extraction yield was achieved than n-hexane and ethanol in Soxhlet extraction. Still, the soybean oil extraction using the same method with ethanol was performed by Rodrigues et al. [103]. The results

The husks are dried, and the remaining oil extracted with solvent; therefore, two oil types are obtained from olives: (1) olive oil, which is pressed without further processing (other than washing, decantation, centrifugation and filtration) and contains less than 3.5% FFA; and (2) pomace oil, which is obtained by solvent extraction of the

Optimization Methods for the Extraction of Vegetable

extraction time, extraction temperature, and solvent-to-fee d ratio on the oil yield was in vestigated using n -hexane and ethyl acetate as extraction solvents. R 2 of the models developed were 0

The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a solvent has lead to several

Green solvents and technologies for oil extraction from

Oilseeds are crucial for the nutritional security of the global population. The conventional technology used for oil extraction from oilseeds is by solvent extraction. In solvent extraction, n-hexane is used as a solvent for its attributes such as simple recovery, non-polar nature, low latent heat of vaporization (330 kJ/kg) and high selectivity to solvents. However, usage of hexane as a

Pro-pressing in expellers also recovers a major portion of oil from these seeds. However, pre-pressed cakes containing 12-20% oil require flaking prior to their solvent extraction for efficient recovery of oil. Solvent extraction plants are either batch or continuous types.

Solvent Extraction Plant for Making Vegetable Oil

The solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oilseed whose oil containing rate is less than 20%, such as soya bean after flaking or it extracts oils from pre-pressed or fully pressed cake of seeds with oil containing rate more than 20%, such as sunflower, peanuts, cottonseed, palm kernel, canola, copra, castor and variety

OILEX is an organization established in 1984 dedicated to the developments of Vegetable Oil Extraction and Processing Industry. We are one of India's reputed manufacturers and exporters of solvent extraction plants and refineries,.

What is solvent extraction?

Solvent extraction is a chemical oil extraction method to process oil out from vegetables, oilseeds and nuts by solvent, and Hexane is the preferred choice. Industrial oil processing for the edible oil generally involves the solvent extraction step which may or may not be preceded by pressing.

How do you extract solvent from a cake?

Solvent extraction is achieved through the grinding of seed. The ground seed or cake is then purged or washed with a petroleum distillate (the most common chemical used is hexane) which releases the oil in the seed. The solvent is then ¡°flashed off¡± by heating the oil in a sealed chamber.

Which raw material is processed in the solvent extraction plant?

In the Solvent Extraction plant, the primary raw material (soya beans) are processed into: Soya bean oil. In the Extrusion facility the high protein soya oil meal is processed into texturised vegetable protein, a meat extender/replacer and vegetarian offering.

What are the methods of oil extraction from oil seeds?

7. Conclusions Oil extraction methods from oil seeds include conventional methods (solvent and mechanical extraction) and nonconventional or improved techniques (supercritical fluid extraction, ultrasound, microwave, and enzyme assisted extraction.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!