Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

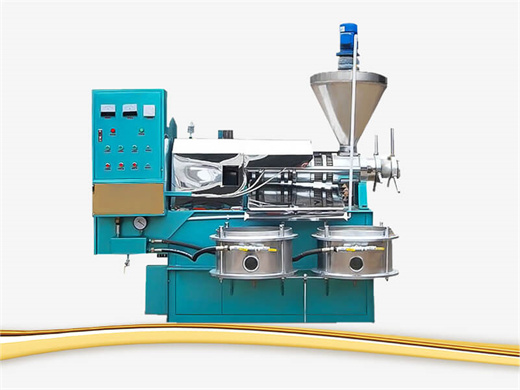

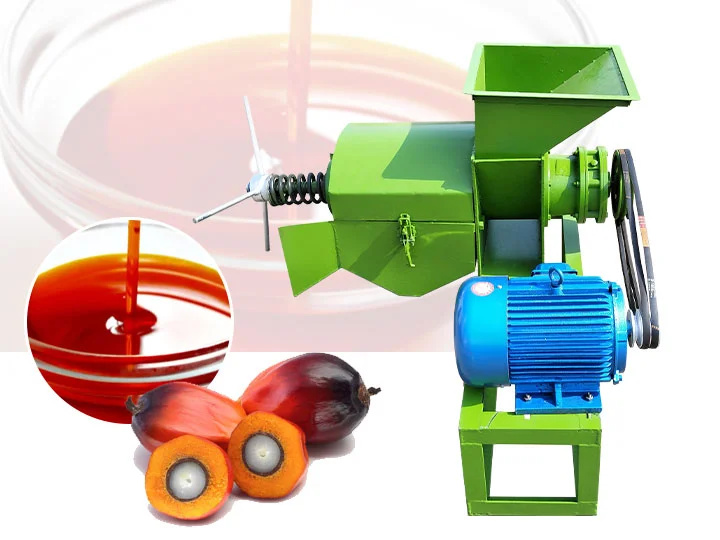

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

professional screw expeller oil processing plant in sudan

- Use: edible oil

- Type: edible oil processing plant

- Voltage: 380V/220V or as required

- Dimension(L*W*H): 2000*1300*1850mm

- Weight: 1250 KG

- Warranty of core components: More than 5 years

- Core Components: Motor

- Oil Function: Press Oil Seeds

- Application: Mini Edible Oil Mill Plant

- Advantage: Energy Saving Low Residual

- Capacity: 40-600kg/h

- Material: Carbon Steel Stainless Steel

- Raw material: Sunflower, etc.

- Processing Types: Screw Pressing

- Used for: various dried oil seeds

- Quality: China Profesional Oil Press Machine

- Product name: Screw Oil Press Machine/cooking Oil Pressing Machine

- Market: sudan

Oil Expeller, Vegetable Oil Extraction Plant Manufacturers

Manufacturer & Exporter of Mechanical Oil Extraction Plant, Solvent Extraction Plant, Cooking Oil Refinery Plant, Fish, Poultry & Animal Feed Plant, Palm Kernel & other Oil Expeller / Oil Press Spare Parts and MSW, Plastic & Industrial Shredder on Turnkey Basis.

This is a large scale palm kernel oil processing project set up in Nigeria. The production capacity is 120 tons per day. It is a complete plant including Seed Cleaner, GOYUM 27

Large Capacity Oil Processing Machine - Oil Expeller

Model Capacity Motor Power Length Breadth Height Weight; GOYUM 2400: 230 – 250 TPD in Pre-pressing: 3 Phase 250 HP 1440 RPM: 17.4 ft: 6.7 ft: 7.5 ft: 27 Ton * (TPD stand for Ton Per Day of Oilseed Crushing Capacity.

40 Ton Per Day Soybean Processing Line is installed on Turnkey Basis in Zambia. A complete soya bean processing plant includes various processes such as soybean cleaning, soybean destoning, soybean cracking, hulls separations, soybean extrusion, oil pressing, crude oil filtration, cake cooling and cake bagging section.

Complete Turnkey Shea Butter Processing Plant Manufacturer

Shea butter is a vegetable fat extracted from kernels of the shea tree. The shea tree grows in the so-called shea belt, which includes roughly 21 countries: Benin, Burkina Faso, Cameroon, Central African Republic, Chad, Ethiopia, Eritrea, Ghana, Guinea-Bissau, Ivory Coast, Mali, Niger, Nigeria, Senegal, Sierra Leone, South Sudan, Sudan, Togo, Uganda, the Democratic Republic of the Congo, Kenya

This is a Fully Automatic Virgin Coconut Oil Processing Plant which is installed in India for our esteemed customer which includes equipment such as Coconut De-Husking Machine, Coconut De-Shelling Machine, Coconut Cutter, Hot Air Drier & Cooler, VCO Oil Expeller Machines, Conveyors, Oil Filter Press with Pump, Storage tanks, Control Panels, Spares, etc.

Complete Canola Oil Processing Plant installed in Australia

This 35 tons per day fully automatic Canola oil mill project is designed and built for our client in Australia including equipment for Seed Cleaner, Seed Conditioner, Screw Press, Screening Tank, Vibro Separator, Filter Press, Screw Conveyor and Bucket Elevator.

Oil Expeller / Oil Press; Filter Press with Pump; Steam Boiler; Bucket Elevator; Screw Conveyor; Oil storage tanks; Control Panel; Niger Seed Oil Mill Plant Process. In the niger seed oil mill, the seed undergoes the following steps: seed cleaning, cooking, oil extraction, oil filtration, oil storage and filling.

Oil Expeller, Vegetable Oil Extraction Plant Manufacturers

Manufacturer & Exporter of Mechanical Oil Extraction Plant, Solvent Extraction Plant, Cooking Oil Refinery Plant, Fish, Poultry & Animal Feed Plant, Palm Kernel & other Oil Expeller / Oil Press Spare Parts and MSW, Plastic & Industrial Shredder on Turnkey Basis.

Cashew nut shells contain 20 – 25 % oil content. After pressing, a residual oil of less than 10 – 12 % is left in the oilcake. The working principle of the Cashew Nut Shell Press is to forcefully push the cashew nut shell through the chamber by the action of the rotating screws.

How to improve oil expeller for Jatropha seed?

Experimental validation of the simulation is used to improve oil expeller for Jatropha seed by fabricating the expeller after the analysis of design by ANSYS FLUENT codes. An oil yield in excess of 98%, as compared to a maximum 75% for existing screw expellers, was achieved in practical runs which is very promising.

What is a good oil yield for a screw expeller?

An oil yield in excess of 98%, as compared to a maximum 75% for existing screw expellers, was achieved in practical runs which is very promising. To access this article, please review the available access options below.

Can screw expeller cater massive Jatropha biomass for oil extraction?

This study is aimed to make efficient screw expeller to cater massive Jatropha biomass for its oil extraction. A computational flow dynamics (CFD) simulation is performed to estimate the pressure developed inside the barrel through screw pressing when the feedstock is Jatropha seed.

How can a CFD study improve the performance of an expeller?

This CFD study has helped to determine the optimum values of important operating variables like rotations per minute (rpm), backpressure caused by frictional forces, and effect of changing feed flow rate on the performance of the expeller. The performance of the expeller is measured by power consumption, yield, and efficiency.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!