Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

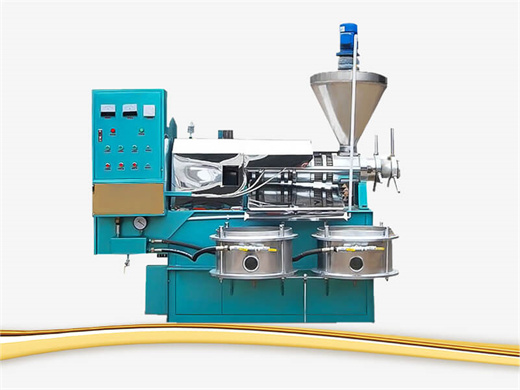

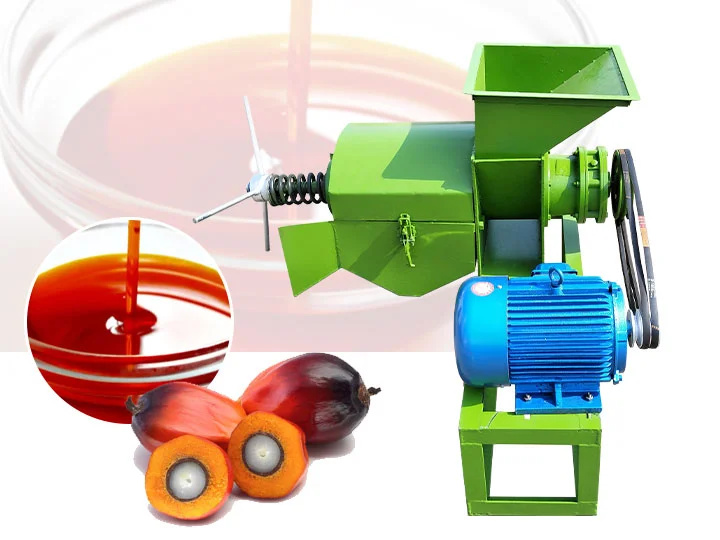

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

the solon quality walnut oil processing plant in botswana

- Use: walnut oil

- Type: walnut oil processing plant

- Production Capacity: 20-150KG/H

- Voltage: 220V/380V

- Dimension(L*W*H): 740*950*1350mm

- Weight: 700 kg

- Name: machine oil press

- Material: 304 Stainless Steel machine oil press

- Model No: OC-H230

- key words: machine oil press

- Function: Press Fresh cooking ,aloe and others

- Capacity: 20-150KG/H machine oil press

- features: high efficiency, cold press,dont break nutrition in oil

- packaging: 1 set/standard export wooden case

- After-sales Service Prded: Free spare parts, Video technical support, Online support

- Market: botswana

automatic castor oil production plant in Botswana

Botswana: Castor Oil Seed Market. This report presents a comprehensive overview of the castor oil seed market in Botswana and a forecast for its development in the next five years. It provides a detailed analysis of. 1ton per hour big full automatic palm oil processing plant

Blended walnut oil: Rather than blend walnut oil with another type of vegetable oil, some retailers may blend together cold-pressed and refined walnut oil. That's because pure, cold-pressed walnut oil can be more expensive. This can be a middle-of-the-road option in terms of flavor, price point, and health benefits.

Walnut Processing: From Hulling To Packing - The Produce Nerd

Walnut Hulling. Walnut hulling is the process of removing the hull, which is a dry outer covering located outside of the shell as the walnuts grow on the tree. As you can see in the picture below, the hull is the green portion located outside of the walnut shells that we are used to seeing.

Applicable Industries: Small oil processing plant, farm product market: Voltage: 110V/220V/380V: Capacity: 100 kg per hour: Dimension(L*W*H) 2320*700*780mm

Walnut Oil Pressing Production Line

Walnut Oil Equipment for Pressing Production Line. Walnut oil press equipment adopts twice pressing method to obtain walnut oil.The equipment mainly includes walnut hulling machine, walnut shelling machine, hydraulic oil press, screw oil press, walnut oil refining equipment, etc. Walnut processing equipment can retain the nutrition in the walnut kernel, has high oil yield and low residual oil

The processing line will allow, among other things, the "shelling of walnuts and the production of innovative derivative products, such as walnut oil or walnut milk". It is also a project with a "strongly export-oriented framework" and will have a "relevant impact on the local economy" in terms of the creation of around 80 direct and indirect

Research progress on Walnut oil: Bioactive compounds, health

Walnut oil is a natural vegetable oil of significant importance due to their nutritional, and intelligence-boosting benefits. Several factors, including the processing parameters and the phytochemical profile, affect walnut oil products’ flavor and color. In addition, storage environment of walnut oil can also affect walnut oil quality.

California Walnut Company, Inc. 24490 Joseph Avenue Los Molinos, CA 96055 Office: (530) 527-2616 Fax: (530) 527-7991

The road to reuse of walnut by-products: A comprehensive

A large amount of by-products including green walnut husk, walnut shell, walnut septum and walnut meal are generated during walnut oil processing. Walnut by-products contain a variety of bioactive compounds that could be applied in food, chemical and biomedical industries as native additives and functional components.

Walnut (Juglans regia L.) kernel oil bodies recovered by. Exploring the biodiversity of plant ω3 PUFA sources (e.g. oilseeds, nuts) while developping at the same time innovative green and minimal processing including aqueous extraction to recover natural oil-in-water emulsions based on plant OBs will contribute to the diversification of plant foods and beverages of nutritional and health

How is walnut oil extracted?

Walnut oil can be extracted using traditional as well as new and green technologies. It is low in saturated fatty acids and high in unsaturated fatty acids (monounsaturated and polyunsaturated fatty acids) as well as being high in other vital nutrients (e.g., selenium, phosphorus, and zinc).

How does the extraction process affect the quality of walnut oil?

The method used for extraction has a significant impact on the quantity and quality of lipids and other important components. It is critical to select a suitable extraction process for the compounds of interest. Scaling walnut oil into commercial production requires proper extraction technologies.

What are the different methods of oil extraction of walnuts?

Market development efforts have intensified; as a result, walnuts are being used more in snacking, baking, and processed foods. The common methods of oil extraction may include the chemical (using a solvent) and mechanical extraction of oil from oilseeds [ 13 ]. The two categories of mechanical techniques are hot press and cold press.

Can walnut shell be used as a plant based bio-sorbent?

Recent advances in the use of walnut ( Juglans regia L.) shell as a valuable plant-based bio-sorbent for the removal of hazardous materials. RSC Adv. 2020, 7026, 7026¨C7047. [ Google Scholar] [ CrossRef] [ Green Version] Goklani, B.; Prapurna, N.P.V.; Srinath, S. Simulation of pyrolytic conversion of Walnut shell waste to value added products.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!