Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

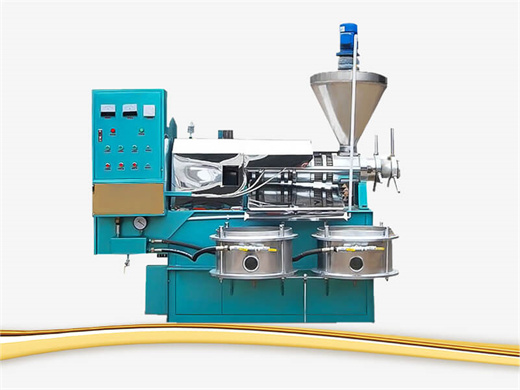

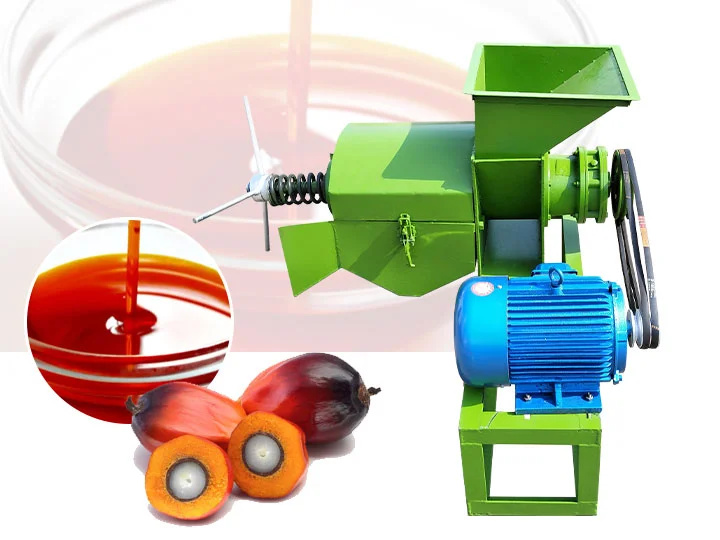

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

sunflower oil extraction equiment in egypt

- Use: sunflower oil

- Type: sunflower oil extraction equipment

- Production Capacity: 100TPD caster oil plant

- Model Number: D-1688

- Voltage: 220V/380V/440V

- Power(W): depend on capacity

- Dimension(L*W*H): 5432*2636*2345

- Weight: 850 KG

- Certification: ISO9001

- After-sales Service Provided: Overseas service center available

- Keywords: LD cooking oil manufacturing process/extractor

- Name: LD cooking oil manufacturing process/extractor

- Material: Stainless steel

- Engineers request: 1-2 engineers

- Oil Grade: 1st,2nd,3rd

- Environment friendly: yes

- Business Methods: oil extraction machine

- oil rate: 20%-98%

- Market: egypt

Low Moq Plant Oil Extraction Machine in Egypt

Low Moq Plant Oil Extraction Machine in Egypt . Use: Cooking Oil; Type:Cooking Oil Extraction Machine; Production Capacity: 10t/24h; motor: 11 kw; Dimension(L*W*H): 1300*3500*1800

Hot Sell Soy Oil Extraction Machine Equiment Price in Egypt . Use: Soybean Oil; Type:Soybean Oil Extraction Machine; Production Capacity: 60sets per year; Power Supply: 380V, 50Hz, 3phase; Dimension(L*W*H): 310X240X380mm; Voltage: 220V/380 V; delivery time: 30 days after deposit Market: Egypt

HOW IS SUNFLOWER OIL EXTRACTED? - Grainvest

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

In this paper, natural sunflower seed oil was used as the raw material to extract mixed fatty acids with potassium hydroxide-methyl alcohol solution, and then benzene and methanol were added for

Separation of Sunflower Oil from Hexane by Use of Composite

Vegetable oil extraction, as performed today by the oilseed-crushing industry, usually involves solvent extraction with commercial hexane. After this step, the vegetable oil–hexane mixture (miscella) must be treated to separate its components by distillation. If solvent-resistant membranes with good permeation properties can be obtained, membrane separation may replace, or be used in

FAS Cairo forecasts Egypt’s soybean, sunflower, and palm oil consumption for food and industrial use in MY 2021/22 at about 2.63 MMT, up 2.33 percent compared to the MY 2020/21 volume of 2.57 million metric tons. From MY 2016/17 to MY 2019/20, Egyptian imports of Palm oil, Sunflower oil and Soy oil accounted for 5.18 MMT.

Oil Mill Plant Setting Up for Beginners - Essential Guide

Once you have decided on the type of oil you want to produce, you need to choose the appropriate oil processing equipment. The basic equipment required to setup an oil mill plant includes seeds processing machiens, oil expeller/oil extraction machines, oil refinery, oil filling machine and more. Our company provides a wealth of information on

Extraction of sunflower oil using ethanol as solvent. The extraction mixture consisted of approximately 10.0 ± 0.1 g of sunflower collets and 180 mL of ethanol (95%, bp 78 °C), corresponding to a collet-to-solvent ratio of 1:18 (g/mL).

Characterization of sunflower oils obtained separately by

only on genetic and environmental factors of sunflower, but also on technological processes of oil extraction (Van Hoed et al., 2010; Fernández-Cuesta et al, 2014). Generally, the oil extraction is based on two main steps: pressing (solid–liquid expression) and solvent extraction. Mechanical and

The conventional procedure for sunflower oil extraction involves seed preparation, mechanical extraction (in which a press cake or oilcake containing 16–24% of oil is obtained after continuous pressing), and a final stage which is the solvent extraction from ground oilcakes or expanded material, known as “collets” (porous cylinders

Which extraction method is best for sunflower seeds?

Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

How is sunflower meal extracted from mineral oil?

The solvent vapor stripped from the mineral oil in the mineral oil stripping step is sent to the vacuum condenser for solvent recovery. After the solvent extraction process, an additional increase of the protein content of sunflower meal can be obtained by tail-end dehulling.

How is sunflower crushed for oil recovery?

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

How does a sunflower extractor recover the solvent pumped to the extractor?

The solvent evaporated from the sunflower meal and the miscella are both recovered in the solvent recovery system within the solvent extraction process area. A typical sunflower plant will recover 99.8¨C99.9% of the solvent pumped to the extractor.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!