Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

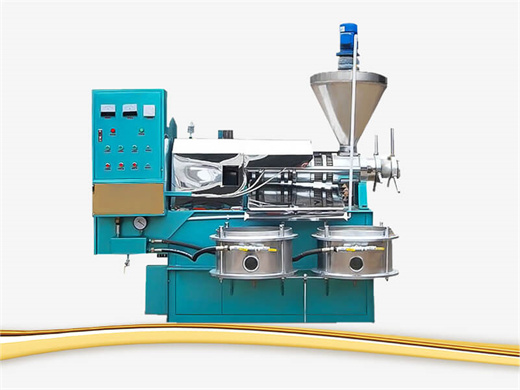

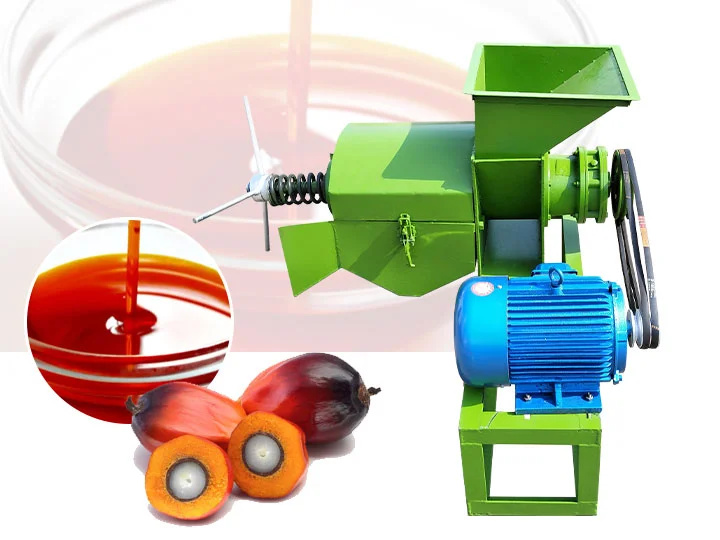

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

approximate sunflower oil extraction per ton in egypt

- Use: sunflower oil

- Type: sunflower oil extraction equipment

- Production Capacity: 75-1250kg/h

- Voltage: 220/110V

- Dimension(L*W*H): 56*20*38cm

- Weight: 20KG

- Core Components: Motor

- Oil key word1: toasted cooking oil

- key word2: oil press machine cost

- key word3: samosa making machine

- key word4: cotton coil 100% pure

- key word5: cooking oil extractor

- key word6: cooking Oil press machine

- key word7: used cooking oil press

- key word8: auto cold screw oil press machine

- key word9: lmond oil making machine

- key word10: mustard oil machine price india fully automatic

- After Warranty Service: Video technical support, Online support

- Certification: CE

- Market: egypt

Global price of Sunflower Oil (PSUNOUSDM) - St. Louis Fed

Graph and download economic data for Global price of Sunflower Oil (PSUNOUSDM) from Jan 1990 to Jun 2024 about oil, World, and price. U.S. Dollars per Metric Ton

Sunflower oil is the non-volatile oil pressed from the seeds of the sunflower (Helianthus annuus). Sunflower oil is commonly used in food as a frying oil, and in cosmetic formulations as an emollient. Sunflower oil is primarily composed of linoleic acid, a polyunsaturated fat, and oleic acid, a monounsaturated fat.

Sunflower Oil Prices – Historical Graph [Realtime Updates]

Crude oil prices: Sunflower oil prices move along with crude oil prices as sunflower oil is often used as a substitute for diesel fuel. The seed’s capacity to produce nearly 600 pounds of oil per acre drives the inclination toward sunflower seeds for biofuel production. Overall, the estimated sunflower oil price in 2030 will be $920.75 per ton.

By carefully examining the costs associated with soybean oil extraction plants, palm oil processing facilities, and sunflower oil production units, we can provide valuable insights to investors in the agricultural and food processing sectors, helping them thrive in a competitive market.

Sunflower oil | Formula, Properties & Application

Introduction to Sunflower Oil. Sunflower oil, scientifically known as Helianthus annuus, is a widely used and versatile cooking oil derived from sunflower seeds. Known for its light color, mild flavor, and high smoke point, it’s a preferred choice for various cooking methods, including frying, sautéing, and roasting. Chemical Composition of

This sunflower oil is used in food and industrial applications that require higher levels of monounsaturated fats and are highly stable when used for frying. Mid-oleic oil, marketed as NuSun™, is a sunflower oil with a lower monounsaturated fat level than high-oleic sunflower oil but a lower saturated fat level than linoleic oil.

Edible Oil Production in Egypt: An Overview

These oils include soybean oil, sunflower oil, corn oil and palm oil. Table 2 (Aswaq Financial Co., 2018) lists the quantities imported of these four oils during recent years. Fig. 1: Cottonseed oil production per year Table 1: Egypt's imports of soybeans. Year Total quantities imported from soybean seed (tons) 2015 1.892.555 2016 1.549.412

sunflower oil cold press machine sunflower in Uganda. Production Capacity: 100T~200TPD; Model Number: GQ-0605; Voltage: 220V/380V; Power(W): according to capacity; Dimension(L*W*H): 5432*2636*2345; Weight: 2000kg; Application: various crude oil lLD sunflower oil, sesame oil; Operating ways: safe and simple; Item: hot sale refined oil production

Sunflower Oil Processing Oil Press Machinery In South Africa

Commercial Screw Cold Sunflower Oil Making Press Machine. 1. High oil quality: meet people health standards.2. High oil yield and purer oil:The equipped vacuum filter is used to remove impurity to ensure the pure oil quality and meet the standards of health quarantine.3.Wide application of different oil seeds:The machine can press more than 20 kinds of oilseeds, such as soybean, peanut, sesame

Complete Sunflower Oil Processing Steps. Undertake 1~100ton/day Sunflower Oil Production Line with Cusotmized Business Plan. Complete Sunflower Oil Manfuacturing Process: Cleaning of seeds, de-hulling, oil pressing, solvent extraction and crude oil refining.

Do Egyptian sunflower hybrids give higher quality oil?

In conclusion, results indicated that the high-oleic and mid-oleic sunflower hybrids cultivated under Egyptian conditions gave higher quality oil. Access to this full-text is provided by De Gruyter. This content is subject to copyright. Terms and conditions apply. ...

Which extraction method is best for sunflower seeds?

Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

What is the evolution of sunflower seed production & acreage?

Evolution of sunflower seed world production (Million Tons, yellow bars) and acreage (Million ha, red bars) 1976-2018 (Source: Oil World, 2019). Evolution of oilseeds production 1975-2019. Evolution of the relative share of 10 oilseeds in Global production (Source: Oil World, 2019). Localisation of the sunflower production.

How is sunflower crushed for oil recovery?

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!