Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

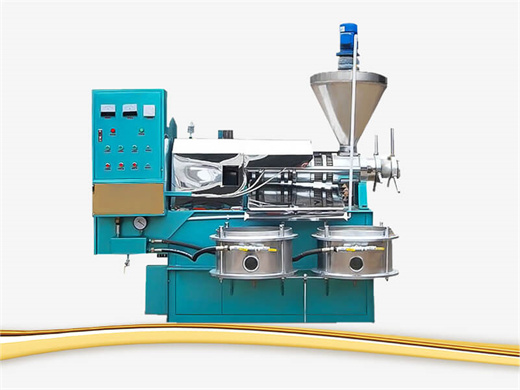

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

products solvent extraction sunflower oil in kenya

- Use: sunflower oil

- Type: sunflower oil extraction equipment

- Production Capacity: 1-600t/d

- Model Number: cooking oil product line

- Voltage: 220V,380V

- Power(W): 550kW

- Dimension(L*W*H): according to customer

- Weight: according to customer

- Certification: ISO&CE&BV

- certificate: ISO9001

- Bank credit rating: AAA

- Capacity: 1t-500t

- Raw material: Vegetable Seed

- final product: cooking oil

- texture: stainless steel and carbon steel

- color: according to customer

- warranty: 1year

- service life: 50years

- service after sale: design workshop | installation | training

- Market: kenya

Small scale extraction sunflower cooking oil press machine in

GEMCO is a reliable manufacturer of vegetable oil machine including sunflower cooking oil making machine small scale sunflower oil press sunflower oil extraction machine in kenya, hydraulic cold expeller press, mechanical oil pressing machine, solvent oil extraction machine, and also customized cooking oil production line and crude oil refinery equipment (like ).

Background One of the most basic needs of mankind is an abundant and reliable food supply. In the modern world, one major source of protein and vegetable oil is from oilseeds, particularly the soybean – an abundant resource which is largely processed using solvent extraction, an efficient and reliable means to separate the high-protein meal solids from the high-energy edible oil.

Vegetable and Cooking Oil Extracting Machine in Kenya Prices

2.5t/d tea seeds oil press, 1t/d oil refining and dewaxing. 3. Nigeria - 30TPD soybean and groundnut oil production line 4. Malaysia - 50T/D fish oil stainless steel oil refinery plant 5. Uzbekistan-80t/d crude sunflower oil and cottonseed cake solvent extraction plant, oil deodorization and dewaxing 6. Bangladesh-50t/d rapeseed pressing plant 7.

The resulting oil is filtered several times in order to achieve a particularly high degree of purity, which is highly valued in the pharmaceutical sector in particular. In Leonberg, we carry out final laboratory analyses on our refined sunflower oil to ensure that it meets our high standards of quality and purity. The oil meets European

Sunflower Oil Processing Plant Oil Making Machine Kenya

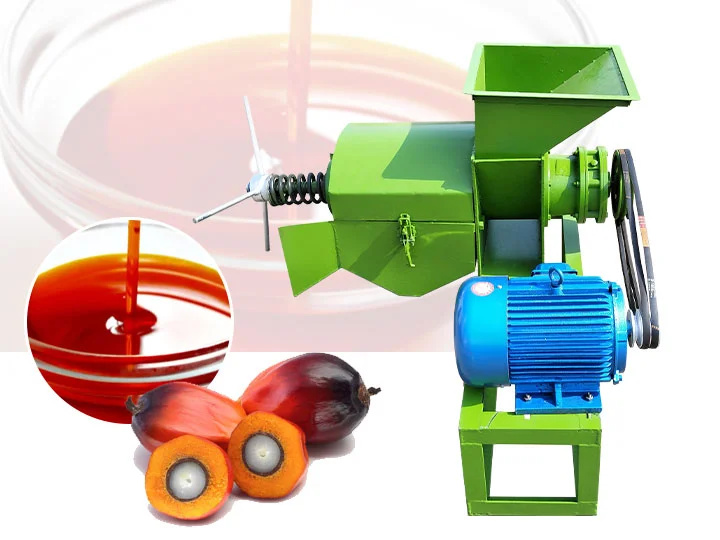

Place the installed screw oil press machine in a stable position, turn on the power, and then put in the material for oil extraction. Sunflower Seeds & Sunflower Oil In Kenya. Sunflower seeds are extremely nutritional seeds packed with vitamins, protein, fibers and some of the essential minerals, as well as healthy fats.

In addition to cold pressing, sunflower oil can also be made using a process known as solvent extraction. This process involves using chemical solvents to extract the oil from the sunflower seeds. After the oil is extracted, it is filtered and processed to remove impurities.

Sunflower Seed Solvent Extraction Plant Process - Oil Expeller

The acceptable temperature for solvent extraction is 55°C and moisture around 8% to 9%. The collets discharged from expander system passed through the drier cooler where there moisture and temperature are reduced to required level and suitable for solvent extraction and transferred to the solvent extraction plant. Solvent Extraction

Sunflower oil extraction is when manufacturers take out the desirable compounds (or oils) from the seed of the sunflower and sell it as is or as an additive in other products. While there are a few different ways manufacturers can go about this, they tend to prefer solvent extraction methods.

V.B Oil Mills Pvt Ltd – SUNPREETHI OILS

V.B Oil Mills Private Limited Established in 1989 in India. Our company has started as batch solvent extraction plant of 50 TPD. We started processing sunflower oil cake. We expanded to continuous solvent extraction plant of 150 TPD. We further established another solvent extraction plant of 100 TPD. we also have refinery of 50 TPD capacity.

Refining sunflower oil through solvent extraction, de-gumming, neutralization, and bleaching can make it more stable and suitable for high-temperature cooking, but doing so will also remove some of the oil's nutrients, flavor, color (resulting in a pale-yellow), free fatty acids, phospholipids, polyphenols, and phytosterols.

How hexane is used in sunflower oil extraction?

Which is where solvent extraction comes to the rescue. Solvent extraction is the part of the sunflower oil making process in which almost every last drop of oil is extracted from the sunflower seeds. Hexane is the most widely used solvent for this. The process begins with the pouring of hexane over the leftover cake from expeller pressing.

Which extraction method is best for sunflower seeds?

Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

How does a sunflower extractor recover the solvent pumped to the extractor?

The solvent evaporated from the sunflower meal and the miscella are both recovered in the solvent recovery system within the solvent extraction process area. A typical sunflower plant will recover 99.8¨C99.9% of the solvent pumped to the extractor.

How is sunflower crushed for oil recovery?

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!