Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

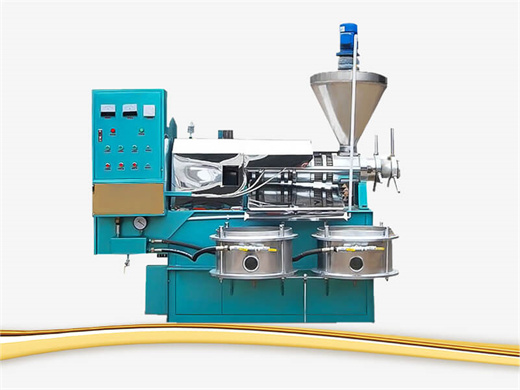

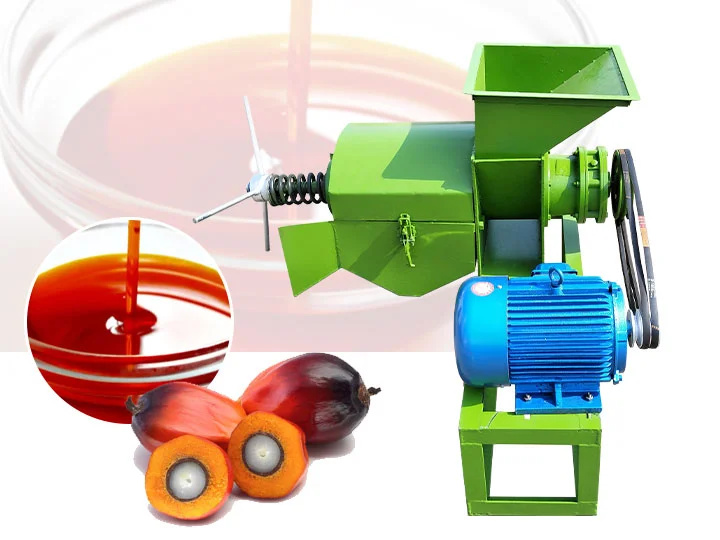

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

high quality sunflower oil neutralising processes in france

- Use: sunflower oil

- Type: sunflower oil extraction equipment

- Production Capacity: High

- Model Number: JX1246, Mustard oil extractor process

- Voltage: Depend on mustard oil extractor capacity

- Power(W): Depend on mustard oil extractor capacity

- Dimension(L*W*H): Depend on mustard oil extractor capacity, Depend on mustard oil extractor capacity

- Weight: Depend on mustard oil extractor capacity

- Steam consumption: 450kg/T

- Waste bleaching earth oil content: Less than 35%

- Color: Based mustard oil extractor capacity

- Residual oil in meal: Less than 1%

- Crude oil moisture and volatile matter: Less than 0.30%

- Market: france

Quality control in the production process of sunflower oil

The typical problem of vegetable oil processing is to ensure the consistency of the output quality. The one parameter that mostly affects quality is the presence of wax, which commands control at all stages of the process (refinement, odours removal, freezing).

Quality Control in Sunflower Oil Extraction. Quality control is essential to ensure that the sunflower oil extracted is of high quality and safe for consumption. We will discuss the various quality control measures that can be implemented during the sunflower oil extraction process, including testing for contaminants, oxidation, and rancidity.

How To Know If Sunflower Oil Is Legit? (The Definitive Guide)

These countries have the experience and expertise to produce high-quality sunflower oil. Additionally, these countries have a long-established reputation for producing quality sunflower oil, so you can be sure the oil you are buying is genuine.

Introduction To Neutralizing Technology. This is the first process of refinery. It is also called the alkali neutralizing process. In every cooking oil there will be some proportion of free fatty acids – ffa that increase the rancidity in the oil and it is harmful to the health.

Study by means of 1H nuclear magnetic resonance of the

This study aimed to compare the frying performance of palm oil (PO) and high oleic sunflower oil (HOSO) during frying aquatic products. The quality change and frying performance of HOSO and PO during frying of fish cakes were investigated.

The results revealed that all these quality attributes are decreased during the chemical refining process, except oil stability which was decreased during neutralizing, bleaching and winterizing

Changes in quality and composition of sunflower oil during

Request PDF | On Sep 1, 2014, Daniela L. Lamas and others published Changes in quality and composition of sunflower oil during enzymatic degumming process | Find, read and cite all the research

Introduction to Sunflower Oil Extraction. Sunflower oil extraction, as the name suggests, is the process of obtaining oil from sunflower seeds. It's a meticulous process that involves several steps to ensure the purity and quality of the final product.

How Is Sunflower Oil Made? (The Step-by-Step Process

This is done to ensure the oil is high-quality and nutritious. The process of filtering and processing sunflower oil is relatively straightforward. First, the oil is passed through a filter to remove any solid particles or debris that might have entered during the extraction process. This helps to ensure the oil is clean and safe for consumption.

FY Extractio is a leading provider of advanced sunflower oil production technology and equipment. With our state-of-the-art processing techniques, we can help you extract the maximum amount of oil from sunflower seeds and produce high-quality, edible oil suitable for a wide range of applications.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!