Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

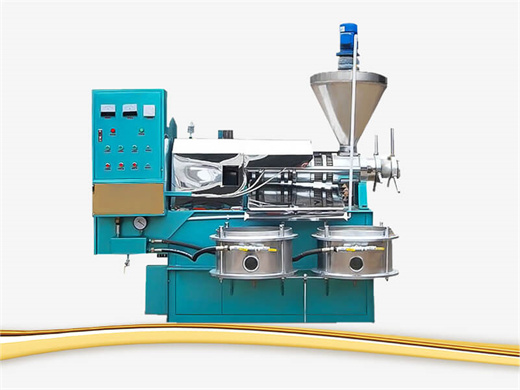

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

sunflower sunflower oil extraction equiment in togo

- Use: sunflower oil

- Type: sunflower oil extraction equipment

- Production Capacity: 1TPD-1000TPD

- Model Number: cooking oil extraction machine

- Voltage: 380V

- Power(W): according to capacity

- Dimension(L*W*H): various with capacity

- Weight: changed with capacity

- Certification: CE and ISO

- Raw material: Vegetable Seed

- Product: 1-10t medium scale cooking fruits processing machine

- Solvent name: n-hexane

- Capacity: 1-3000TPD cooking oil extraction machine

- Oil content in Sunflower: from 18-22%

- Oil residues: less than 1%

- Function: cooking oil extraction machine

- Manufacturing experience: 40 years

- Warranty: 1 year

- Material of equipment: stainless steel and carbon steel

- Market: togo

How to extract oil from sunflower ? What equipment is needed?

sunflower oil is typically obtained through either sunflower oil pressing equipment or sunflower oil solvent extraction equipment. We will discuss these two types of sunflower oil extraction equipment, and methods required.

Looking for Sunflower Seed Oil Extraction Machine Manufacturers? We are among the reputed organizations, engaged in exporting of Oil Extraction Machines.

sunflower oil processing plant in togo | oil extraction

We are leading professional edible oil and grease engineering company engaged in edible oil and grease extraction, refining, dewaxing, separation and other technical design research and engineering construction.

30tdp sunflower solvent equipment oil extraction in togo. Usage: Other; Type: Cooking Oil Press Machine; Production Capacity: 5TPD-100TPD; Voltage: 380V/50HZ

sunflower oil equipment | oil extraction machine supplier

equipment for sunflower oil press 50-100tpd in india. Usage: Sunflower kernel machinery malaysia; Production Capacity: 20-2000TPD; Model Number: PZ Lemongrass jatropha Sunflower oil extraction plant machine

In this post, we will explore the sunflower oil extraction process, the different methods involved, and the factors affecting the yield and quality of the oil.

sunflower oil equipment in togo | oil extraction machine supplier

guatemala sunflower oil production equipment in togo. Usage: Sunflower Oil, Sunflower EDIBLE OIL; Type: Oil Extraction Machine; Production Capacity: 50tpd

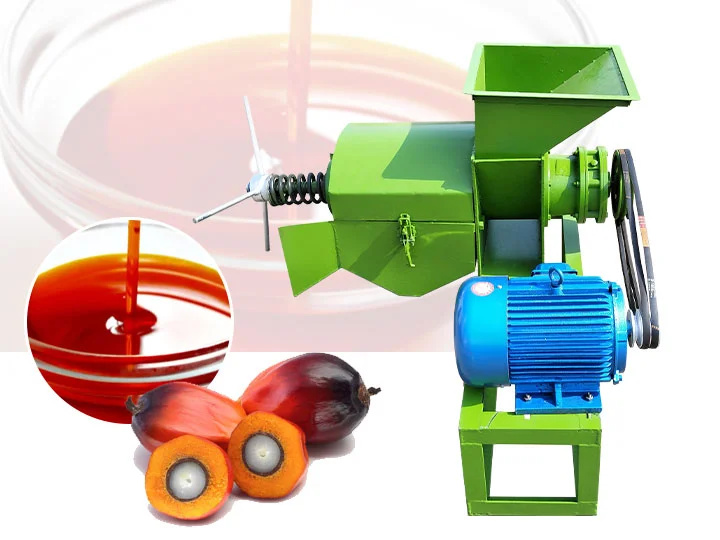

Sunflower oil extraction is when manufacturers take out the desirable compounds (or oils) from the seed of the sunflower and sell it as is or as an additive in other products. While there are a few different ways manufacturers can go about this, they tend to prefer solvent extraction methods.

#1 Sunflower Oil Production Line For Sunflower Oil Plant

Starting your sunflower oil manufacturing with FY Extractio’s production line offers numerous benefits. Our advanced oil extraction technology and equipment are designed to help you extract the maximum amount of oil from sunflower seeds, making it a cost-effective solution for small sunflower oil plants.

What are the stages of sunflower oil extraction? Sunflower Oil Extraction Stages. Read: Advantages of Green Leaf Manuring. Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. How is sunflower […]

Which extraction method is best for sunflower seeds?

Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

How is sunflower crushed for oil recovery?

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

How does a sunflower extractor recover the solvent pumped to the extractor?

The solvent evaporated from the sunflower meal and the miscella are both recovered in the solvent recovery system within the solvent extraction process area. A typical sunflower plant will recover 99.8¨C99.9% of the solvent pumped to the extractor.

How is sunflower meal extracted from solvent extraction process?

Therefore, the sunflower meal from the solvent extraction process is generally screened. The small particles passing through the screen are separated from the large granules and lumps, which pass over the screen and go to a hammer mill. The hammer mill reduces the lumps and large granules to a uniform, fine granule size.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!