Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

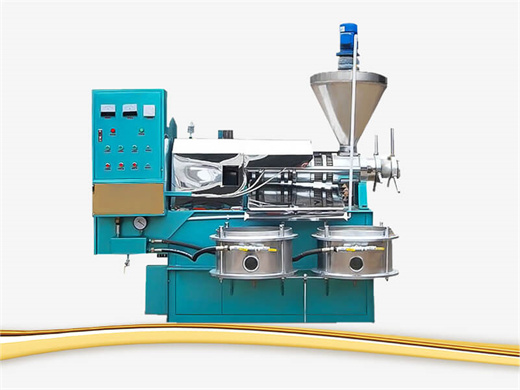

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

low consumption sunflower oil extraction equipment in pakistan

- Use: sunflower oil

- Type: sunflower oil extraction equipment

- Production Capacity: 600kg/h

- Voltage: contact us

- Dimension(L*W*H): 43.5*27.5*28cm

- Weight: 12 KG

- Warranty: 3 months

- Core Components: contact us

- Oil MOQ: 2PCS

- Application: Family

- Color: Customizable Color

- Advantage: Easy Operation

- Shell Material: Stainless Steel Wire Drawing

- Product Size: 43.5*27.5*28cm

- Control method: Intelligent panel control

- Material: Full stainless steel housing

- Pressing speed: 6-11 kg/h

- Market: pakistan

turkey sunflower oil extraction machine supplier in pakistan

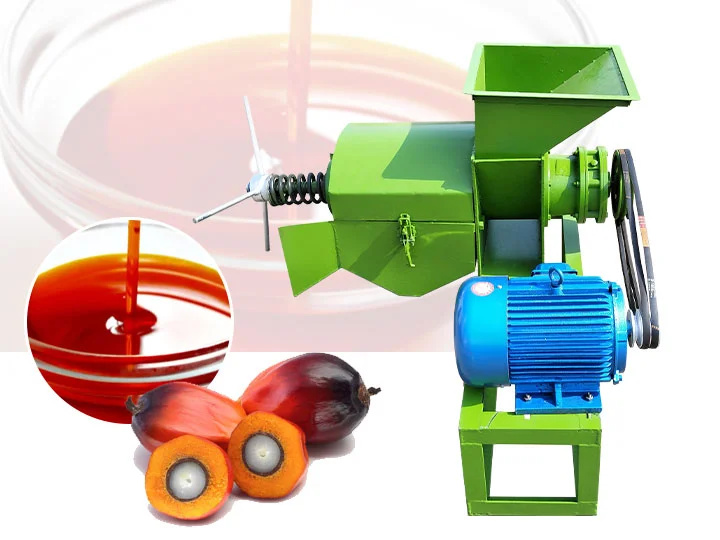

Pressing type: Screw Sunflower oil press machine; Power consumption: Enery-saving Sunflower oil press machine; Raw material: Sunflower and other vegetable oil seeds; Certification: CE ISO oil press; Sunflower oil extraction machines can also be equipped with additional equipment such as oil refining equipment and packaging equipment to produce

Features of Sunflower Oil Production Line Characteristics of the oil pressing and extracting. Compared with other oil extraction methods, the oil pre-pressing has the advantages of simple process, less supporting equipment, strong adaptability to oil varieties, flexible production, good oil quality, light color, and pure flavor.

Effect of refining on quality and composition of sunflower oil

Sunflower oil is used as a premium salad oil due to the presence of high ratio of polyunsaturated-to-saturated fatty acids. Refined sunflower oil has found wide acceptance because of its high polyunsaturated fatty acid content, bland flavour, good storage stability and low viscosity (Semwal et al. 1996). Refined sunflower oil has emerged as one

Production Process for Sunflower Seed Oil. Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%.

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

Steps Involved in Sunflower Oil Extraction Process. The sunflower oil extraction process involves several steps, including cleaning, dehulling, cooking, pressing, and refining. Cleaning involves removing any foreign material and impurities from the seeds. The dehulling process helps to remove the outer shell of the seed to access the oil-rich

Learn about the oil extraction process, equipment such as a sunflower oil press, most commonly processed oilseeds & the use of their oils. Skip to content Call Us Today: 1-937-773-3420

sunflower oil press in pakistan | oil extraction machine supplier

low cost and consumption sunflower oil press in pakistan. Usage: Sunflower Oil; Type: Cold & Hot Pressing Machine, oil dewaxing machine hexane; Production Capacity: 5TPD-500TPD; Model Number: YZYZ-5; Voltage: Design according to customer demand; Power(W): According to customers' need; Dimension(L*W*H): According to customers' need

Sunflower oil can also be used to condition and nourish hair. Overall, sunflower oil is a healthy and nutritious oil that can be used in a variety of ways. From cooking and baking to skin and hair care, this versatile oil has many uses. Nutritional Values of Sunflower Oil. Sunflower oil is a nutritious oil that provides a variety of health

low consumption sunflower oil extraction equipment in malaysia

Extracting and refining steps of sunflower oil. | Download. Figure 1 represents schematically the main steps of sunflower oil extraction and refining. the suitable quantity of sunflower oil consumption varies according to individuals aged 8, 18, and 30. In this article, we will discuss the complete sunflower oil production process in detail.

low power consumption sunflower oil extraction – High Edible oil Higher oil rete low consumption sunflower oil expeller machinery plant is utilizing the principle of cottonseed oil manufacturing process can be dissolve...

Which extraction method is best for sunflower seeds?

Therefore, prepress solvent extraction, with the highest oil recovery yield, is the process method utilized today for the majority of the sunflower seed that is crushed globally.

How is sunflower crushed for oil recovery?

Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed.

How is sunflower meal extracted from solvent extraction process?

Therefore, the sunflower meal from the solvent extraction process is generally screened. The small particles passing through the screen are separated from the large granules and lumps, which pass over the screen and go to a hammer mill. The hammer mill reduces the lumps and large granules to a uniform, fine granule size.

How does a sunflower extractor work?

A typical sunflower plant will recover 99.8¨C99.9% of the solvent pumped to the extractor. Solvent vapors from the desolventizer toaster are primarily condensed in the shell side of the first evaporator of miscella distillation for heat recovery purposes. The remaining vapors pass to an atmospheric condenser, to be condensed.

REQUEST A QUOTE

Submit your enquiry, Our professional team will reply to you within one business day.Please feel free to contact us!